About us

In production since 1939 as a part of Bata companies. Organized around rubber compound facility, producing rubber boots, cemented shoes, vulcanized shoes as well as rubber outsoles, semi-products and rubber compounds.

Services

WHAT WE DO

CENTRAL MILL / READY-MADE MILL

Development of rubber mixtures according to customer requirements | Mixing of rubber mixtures / Mixing up rubber mixtures | Covering of rubber on textile / neoprene | Pulling of rubber mixtures | Cutting of parts from rubber mixtures | Mixing and cutting rubber loads for pressing of soles | Cutting of unending rubber straps to the required measure – batchfeeder

LEATHER HANDLING, TEXTILE AND NEOPRENE CUTTING

Textile cutting with GERBER machine - choice of shapes, without the production of cutting equipment | Cutting of textile with hydraulic cutting machines | Cutting of leather skin with hydraulic cutting machines | Cutting of textile straps to trimmings (Molino material) | Cutting of textile to bridge mower

PRESSING

Pressing with hydraulic multi-stage pressing lines 800x400mm / 5 lines / 2 multi-stage lines / 4 station lines | Pressing of rubber mouldings with hydraulic multi-stage pressing ines 400x400 mm, 2 lines / 1 multi-stage line / 1 station line | Pressing with hydraulic multi-stage pressing lines 1200x800mm / 6 lines / 6 multi-stage lines | Splitting of microporous and rubber materials - size max 1300mm width note without length limitation | Screen printing on parts from various materials | UV printer Mimaki UJF 6042Mk ll

SEWING

Sewing of shoe uppers - textile, leather | Sewing of products except ready-made production

FOOTWEAR MANUFACTURE

Rubber footwear - stitching method of production | Pressed rubber-textile footwear | Glued footwear

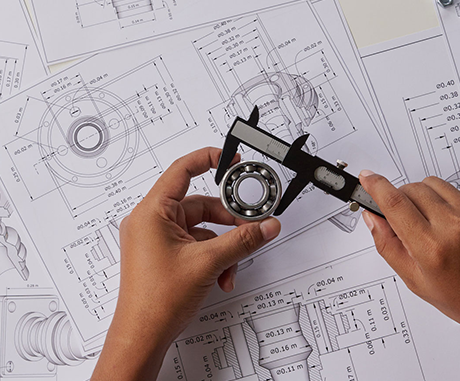

Our know-how and technological base

built for decades in the field of footwear production, giving us a solid basis for further expansion of activities in the field of industrial applications. Despite the global situation, which brings new challenges every day, the decision to further diversify the product portfolio proves to be the right way to greater economic stability of Vulkan Partizánske a.s.

To achieve this, we strengthen our team with experienced professionals from other industries. Investments in new production technologies expand our production possibilities. Quality, delivery efficiency and economic attractiveness combined with flexibility in solving your requirements are essential elements for successful cooperation. We look forward to your projects.

Peter Urban

Manager for Business development and sales

Industrial applications

Mob.:+421 903 143 438

E-mail: peter.urban@vulkan.sk

INDUSTRIAL APPLICATIONS suitable in Vulkan Partizánske a.s.:

Industrial sewing

• Industrial sewing of the special materials

• Sewing for automotive seats

• Sewing of the car mat

• Applications for defense and medical use

Vulcanized Parts

• Vulcanized rubber parts

• Vulcanizer rubber/metal, rubber/plastic parts

• Applications for hole range of industries

• Construction, agriculture, food processing, sea freight

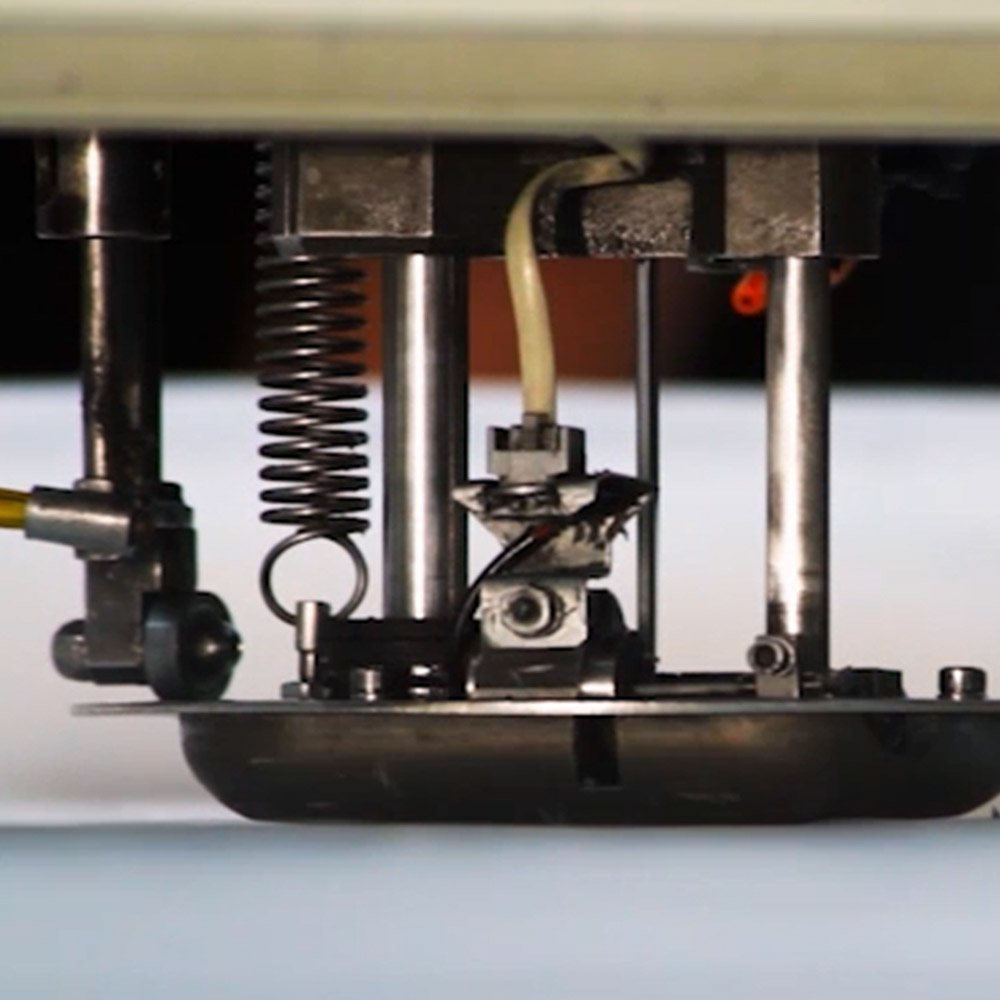

Subassembly

• Subassembly of the different level

• Single purpose assembly machine

• Complex assembly, required recent skills

• Big variation of the applications

Finalization and finetunning

• Cleaning of the overmoldings

• Packing of the parts

• Visual quality checking

• 1st and 2nd level of cooperation